- Easy application without the need for expert skills in metallic decoration

- Excellent luster and stable quality achieved by vapor-deposition technology

- People- and environment-friendly: no use of solvent, and little waste

- Reasonable prices of hot stamping machines enable reduction of investment costs

- Applicable to various usage contexts such as printing of small characters and multiple-surface application

Hot stamping foil

Product Features

What is Hot Stamping Foil?

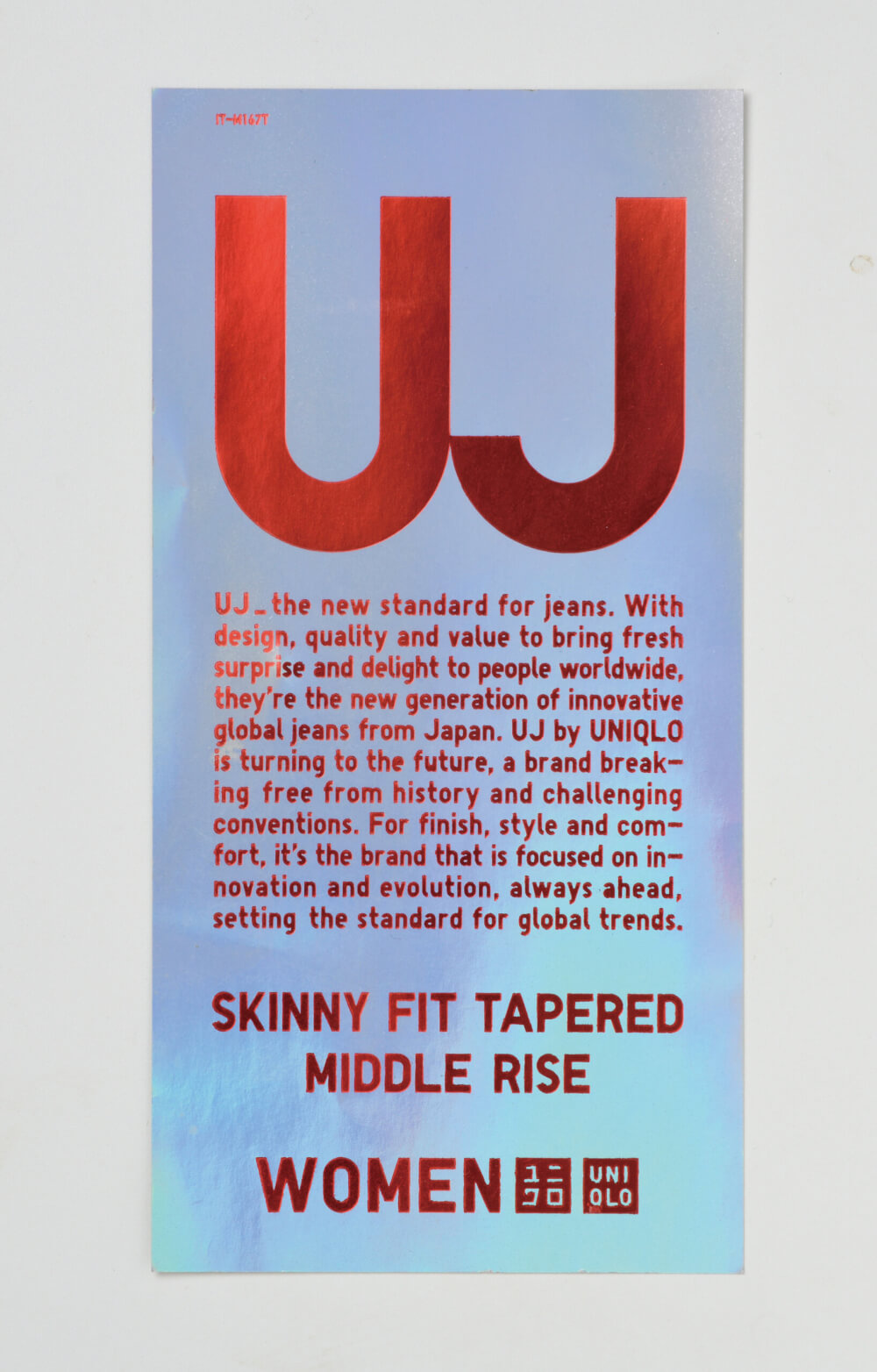

- Hot stamping foil is a material for application to the surface of plastic, wood and metal as well as painted surfaces by hot stamping technology. It is now widely used for home appliances, mobile phones, automobile components, cosmetic containers, daily commodities, toys and building materials.

- We provide hot stamping foils of many types, designs and colors in accordance to the specific objective.

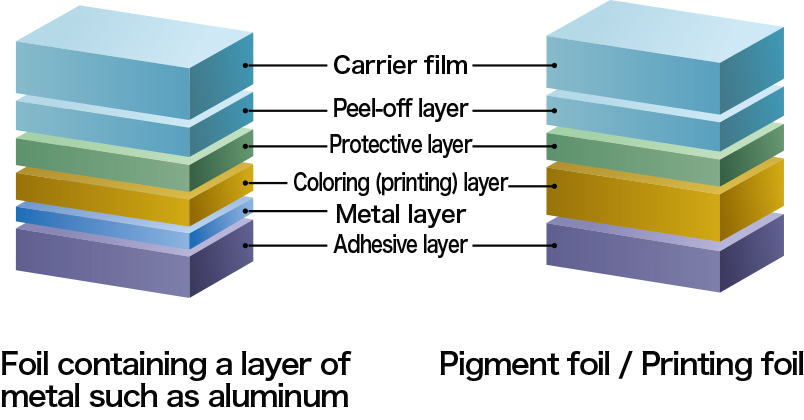

Structure of Hot Stamping Foil

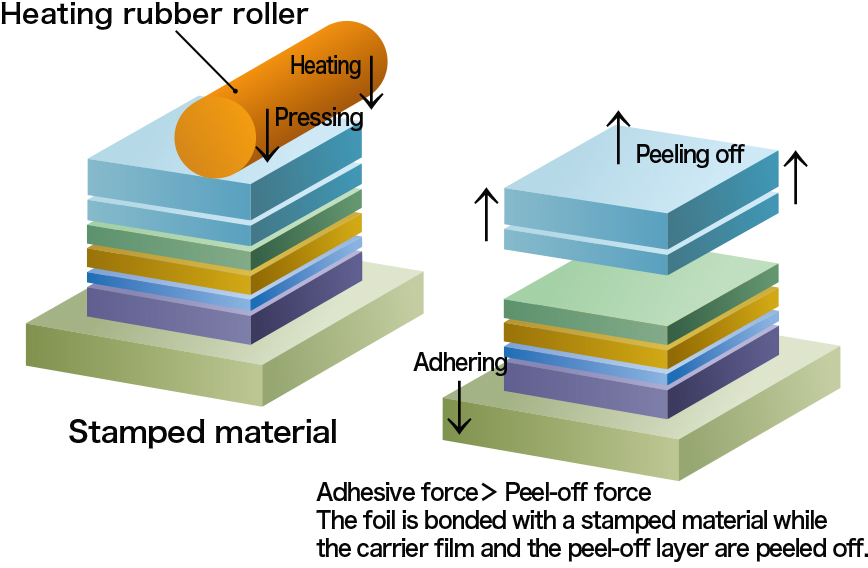

Mechanism of Hot Stamping

Multi-color Stamping Foil

- Silkscreen printing with a high screening property enables 175-dot printing of color separation images and fine characters.

- Foil containing a vapor-deposit layer is available.

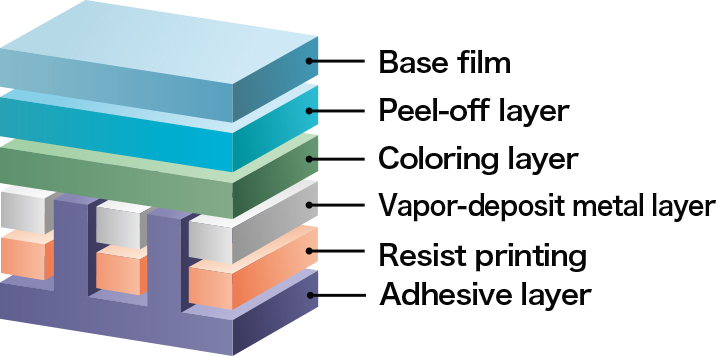

Structure of Partial Vapor-Deposition Foil

*The figure shows the structure of foil when resist printing using alkali-resistant ink and alkali washing are conducted after vapor-deposition.

Types of Hot Stamping Foil

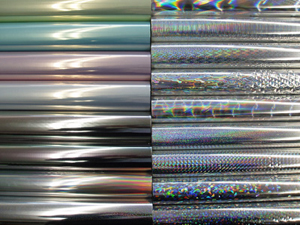

- Metallic foil (vacuum vapor-deposition foil)

- Pigment foil (coating foil)

- Multi-color Stamping Foil

- Special foils, such as:

hairline foil for superior metallic effects, special metal foils other than aluminum foils (chrome, stainless steel, tin, etc.), metallic hard-coating foil, transparent hard-coating foil, and in-mold foil - UVR (ultraviolet reactive) foil

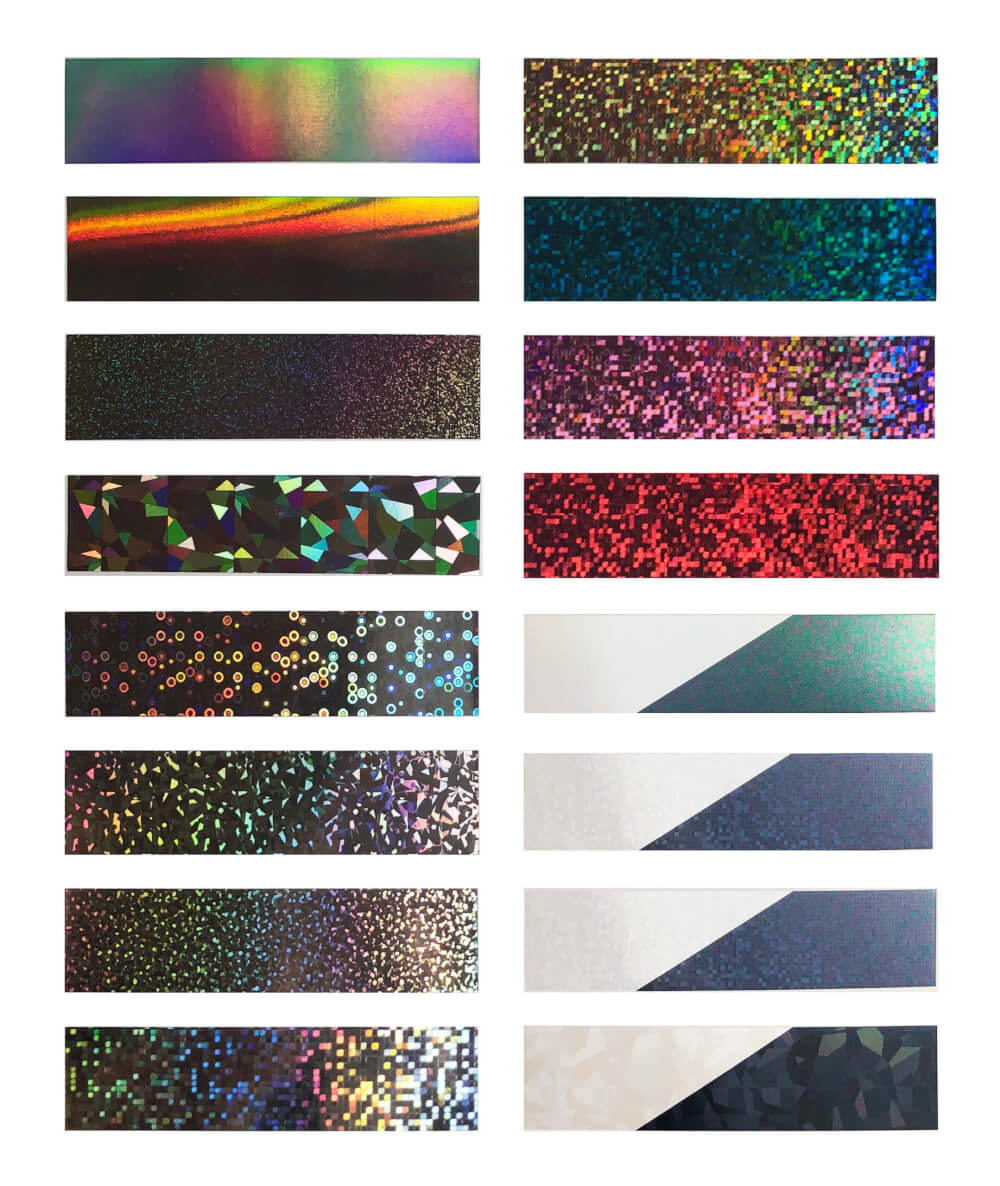

Stamped characters take on a pale luminosity when lit by ultraviolet light. The metallic/hologram effect combined with the luminescence created by UV radiation is an effective tool for security purposes. - Hologram foil

This foil becomes luminous in rainbow colors when lit. Various color patterns are available. - FINE HALF (Half vapor-deposited foil)

Half-metallic foil is produced by vacuum vapor-deposition technology. It looks metallic under normal conditions, but transmits visible light when lit by an LED from the back. The foil can be conveniently applied to display panels of home appliances. Various types are available with a transmission rate of 10%~0%, depending on the thickness of the aluminum layer.